3D printing based in copper is done by Selective Laser Melting (SLM). Copper is a complex material to procces by this technology due to its high reflectivity. This characteristic makes that part of the laser energy needed for the piece manufacture is absorbed by the powder. To manufacture pieces using a 90% purity copper powder is it neccessary to use an equipment with specialised laser and high knowledge of this technology and the material.

To 3D print with copper, high expertise in SLM technology and specific laser conditions are necessary to effectively melt the powder. Factors such as laser power, optimal part design and substrate positioning will be crucial for higher part yield.

Using the technology we have at Addimen, we can manufacture heat exchangers in pure CU 99.9 copper using SLM. By combining this material with additive manufacturing, it is possible to obtain inductors or heat exchangers with optimal geometries for each process that would not be possible using conventional machining techniques, thus improving energy exchange with virtually no losses.

Additive manufacturing of GrCop42 allows us to produce watertight inductors with geometries optimised to fit the target part, significantly improving heat transfer. In addition, it enables the manufacture of complex designs in a single piece, eliminating the need for welds. These welds, common in traditional processes, are often weak points where failures originate. By avoiding them, reliability is increased and the service life of the inductor is extended.

Types

Features

Benefits

The high thermal and electrical conductivities of copper, combined with optimized designs, make it possible to optimize the designs to reduce energy losses of conductive components. It has high corrosion resistance and mechanical properties.

Through the technology we have in Addimen, we can manufacture pure copper heat exchangers by SLM. Thanks to the combination of this material with additive manufacturing, it is possible to obtain inductors or heat exchangers with optimal geometries for each process that would not be possible through conventional machining techniques, thus improving the energy exchange with almost no losses.

Step 1: 3D file

Send us your 3D file ready for printing. If you do not have the file, send us the piece and we will generate the CAD file.

If you need a design from scratch, our designers will be happy to make proposals.

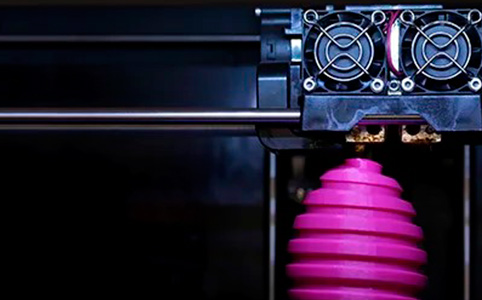

Step 2: 3D printing

We generate the process file adapted to the technology and material to be used in the manufacture of your part.

We prepare and condition the printer to ensure optimal quality.

Step 3: Cleaning and post-processing

This step is key to meeting your requirements and one in which we are highly specialised.

The removal of printing supports, heat treatments and surface finishing (blasting, polishing, machining) are the most common post-processing steps.

Generally most of the copper uses are for pieces that requires high thermal or electrical conductivity. Moreover, due to its ductility, mechanical resistance and good performance to corrosion, it is the ideal material for electrical applications in energy-efficent equipment.

Heat exchangers

Inductors

Electrical and electronic components

Construction industry

Instant quote

If you require more information or advice about our copper 3D printing services, please contact us. One of our specialists will contact you as soon as possible.

Ask for a free quote

SELECTIVE LASER MELTING (SLM)

Renishaw AM500S Flex

The Renishaw AM500S Flex is made for industry 4.0 process methods with optical system control and system processes.

Its 500 W laser enables exceptional precision for manufacturing components with > 99.9% density, maximum strength and ductility.

Workload: The construction volume is 250x250x350mm

Flexibility: The versatility of its design and the possibility of generating new process parameters make this equipment ideal for working with many different materials.

In addition to Copperl we offer 3D printing with metal in the following materials. Take a look and decide which one best suits your needs.

+34 946 941 301

Addimen is a company specialising in professional 3D printing of high added-value parts.

Our designs and manufacturing processes are applied to prototypes, mould inserts, spare parts on demand, and industrial process tools.

Copyright 2025 Addimen. All rights reserved. | Quality policy | Legal notice and privacy policy | Cookie policy

SERVICES

CONTACT

+34 946 941 301

Monday to friday

8:00 - 18:00h

info@addimen.com

Pol. Ind. Astikene -Errotazarre Kalea nº34

48160 Derio (Bizkaia)

ESPAÑA

Anillo Vial Fray Junípero Serra #2601 - 301

Col. Juriquilla Santa Fé

76230, Querétaro, Querétaro

(442)241-0560 MÉXICO