Inconel 718 is a nickel superalloy that offers exceptional heat resistance, maintaining its structural properties up to 650° C. This superalloy is comprised of 55% nickel, 21% iron, and chrome, as well as other less concentrated elements. The parts printed with Inconel possess a high range or working temperatures (from -250 °C up to 650 °C) meaning that they are used in sectors associated with extreme temperatures, such as turbines, heat exchangers, engines, or cryogenic devices.

To 3D print with inconel, it is especially important to control the heat warps that occur during the melting and solidifying of the powder layers.

Choosing the correct support strategy in accordance with the geometrics of the part is essential to guarantee the dimensional tolerance.

Types

Features

Benefits

Inconel is highly resistant to oxidation and corrosion at high temperatures and also has a high creep resistance. Thanks to its highly resistant properties, its material corrosion resistance, and its ability to be used at high temperatures, Inconel 718 is a superalloy that has been used in the development of turbojet engines for aircrafts, among other applications. When used for 3D printing, a lot of the material is used, producing minimal scrap, something which is particularly important for high cost and added value materials such as Inconel.

Parts printed with Inconel usually require heat treatment to improve the mechanical properties of the material following its manufacture. The first option is to carry out a solution heat treatment which can increase the mechanical resistance by up to 40%. If its use requires, special high-pressure treatments can also be applied such as Hot Isostatic Pressure (HIP) to remove any microporous material or microsegregation from any left-over alloys.

Step 1: 3D file

Send us your 3D file ready for printing. If you do not have the file, send us the piece and we will generate the CAD file.

If you need a design from scratch, our designers will be happy to make proposals.

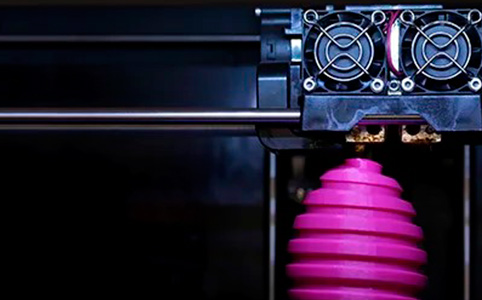

Step 2: 3D printing

We generate the process file adapted to the technology and material to be used in the manufacture of your part.

We prepare and condition the printer to ensure optimal quality.

Step 3: Cleaning and post-processing

This step is key to meeting your requirements and one in which we are highly specialised.

The removal of printing supports, heat treatments and surface finishing (blasting, polishing, machining) are the most common post-processing steps.

Inconel is the ideal material for the aerospace, automotive, and industrial sectors to be used in operations that require a high temperature.

Engines

Heat exchangers

Turbine blades

Nuclear energy

Instant quote

If you require more information or advice about our Inconel 3D printing services, please contact us. One of our specialists will contact you as soon as possible.

Ask for a free quote

SELECTIVE LASER MELTING (SLM)

Renishaw AM500S Flex

The Renishaw AM500S Flex is made for industry 4.0 process methods with optical system control and system processes.

Its 500 W laser enables exceptional precision for manufacturing components with > 99.9% density, maximum strength and ductility.

Workload: The construction volume is 250x250x350mm

Flexibility: The versatility of its design and the possibility of generating new process parameters make this equipment ideal for working with many different materials.

In addition to Inconel we offer 3D printing with metal in the following materials. Take a look and decide which one best suits your needs.

+34 946 941 301

Addimen is a company specialising in professional 3D printing of high added-value parts.

Our designs and manufacturing processes are applied to prototypes, mould inserts, spare parts on demand, and industrial process tools.

Copyright 2025 Addimen. All rights reserved. | Quality policy | Legal notice and privacy policy | Cookie policy

SERVICES

CONTACT

+34 946 941 301

Monday to friday

8:00 - 18:00h

info@addimen.com

Pol. Ind. Astikene -Errotazarre Kalea nº34

48160 Derio (Bizkaia)

ESPAÑA

Anillo Vial Fray Junípero Serra #2601 - 301

Col. Juriquilla Santa Fé

76230, Querétaro, Querétaro

(442)241-0560 MÉXICO