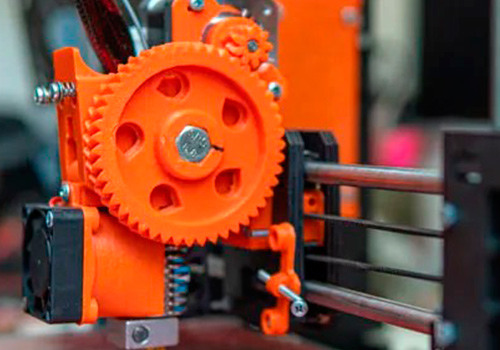

Thermoplastic polymers or plastics can be melted and solidified repeatedly while retaining their intrinsic properties. This is the characteristic utilized by the 3D printing technology known as Fused Deposition Modeling (FDM). Plastic 3D printers using FDM melt a filament of a thermoplastic polymer to deposit it onto a previously deposited solid layer, so that the heat from the melted material re-melts the solidified layer to adhere both layers and form a single printed piece. This layer-to-layer adhesion is also promoted by the pressure exerted by the molten material exiting the 3D printer onto the solid layer.

The wide range of filaments available for professional plastic printers means that this technology can be applied to almost any sector. At Addimen we are able to print standard plastics or commodities and high-performance technical plastics. In the case of more advanced plastics such as PEEK or PEI, their complex processing means that we have to individually analyse each part to determine if they can be manufactured.

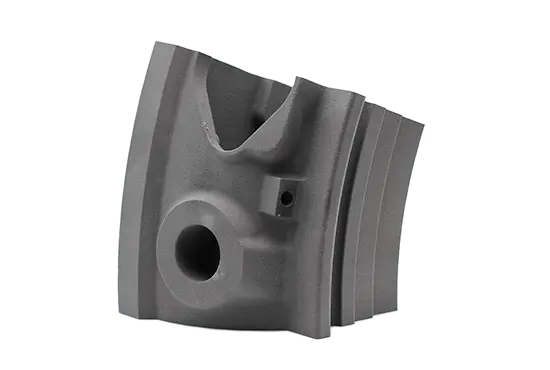

PA12 is the most versatile and widely used material in SLS/MJF 3D printing. It offers an excellent balance between mechanical strength, flexibility and chemical stability, making it ideal for both prototypes and end-use parts.

PA12 GB is a variant reinforced with glass microspheres, which increases rigidity and dimensional stability, ideal for applications requiring structural strength and precision.

PP is a lightweight, flexible material with excellent chemical resistance, perfect for applications where low weight and compatibility with aggressive fluids or chemicals are required.

TPU is a flexible and elastic material for 3D printing, with excellent resistance to abrasion and wear. Ideal for manufacturing parts that require flexibility and shock absorption.

Instant quote

If you require more information or advice about our plastic 3D printing services, please contact us. One of our specialists will contact you as soon as possible.

Ask for a free quote

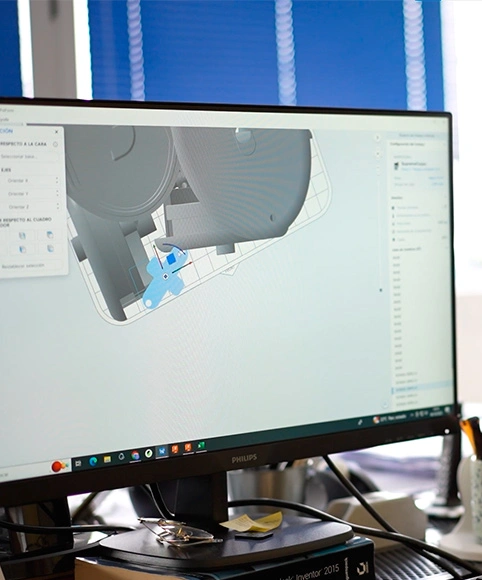

Step 1: 3D file

Send us your 3D file ready for printing. If you do not have the file, send us the piece and we will generate the CAD file.

If you need a design from scratch, our designers will be happy to make proposals.

Step 2: 3D printing

We generate the process file adapted to the technology and material to be used in the manufacture of your part.

We prepare and condition the printer to ensure optimal quality.

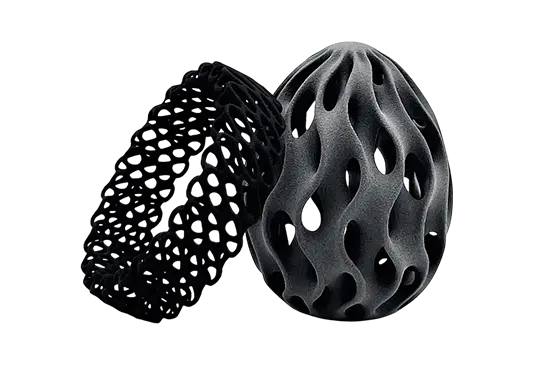

Step 3: Cleaning and post-processing

This step is key to meeting your requirements and one in which we are highly specialised.

The removal of printing supports, heat treatments and surface finishing (blasting, polishing, machining) are the most common post-processing steps.

The most common post-processing techniques are:

+34 946 941 301

Addimen is a company specialising in professional 3D printing of high added-value parts.

Our designs and manufacturing processes are applied to prototypes, mould inserts, spare parts on demand, and industrial process tools.

Copyright 2025 Addimen. All rights reserved. | Quality policy | Legal notice and privacy policy | Cookie policy

SERVICES

CONTACT

+34 946 941 301

Monday to friday

8:00 - 18:00h

info@addimen.com

Pol. Ind. Astikene -Errotazarre Kalea nº34

48160 Derio (Bizkaia)

ESPAÑA

Anillo Vial Fray Junípero Serra #2601 - 301

Col. Juriquilla Santa Fé

76230, Querétaro, Querétaro

(442)241-0560 MÉXICO