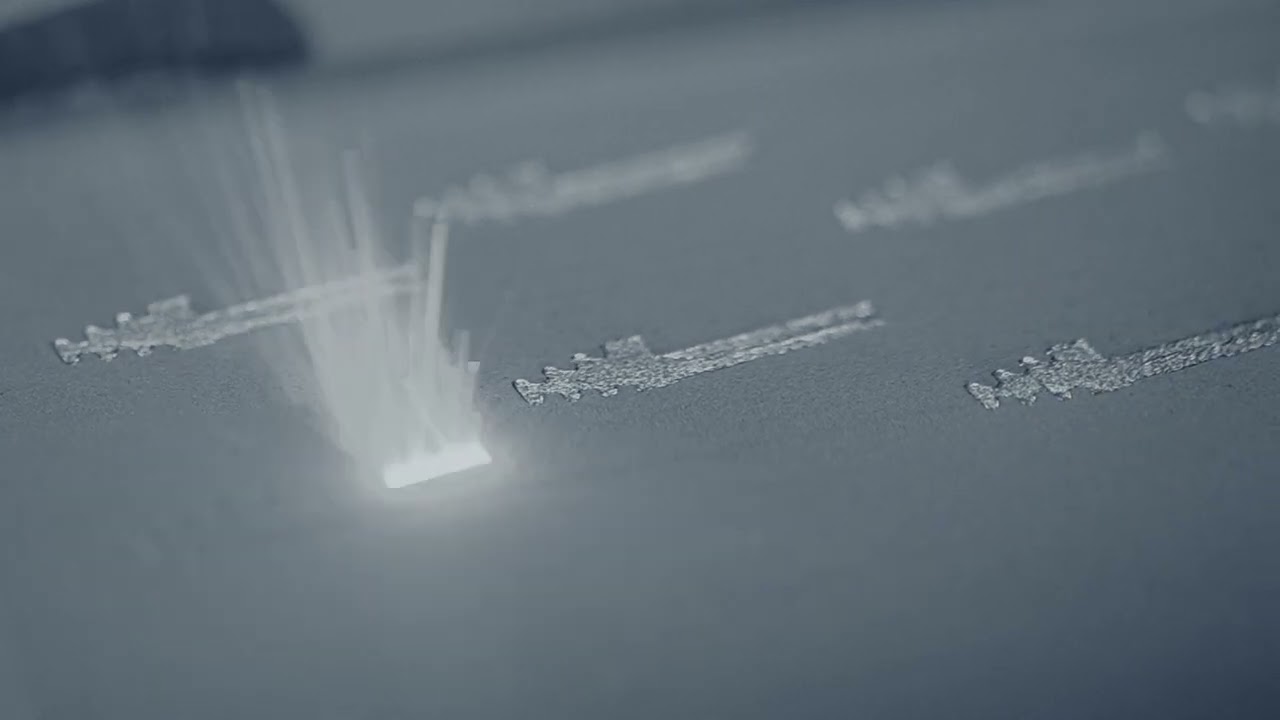

3D printing with PA12

Nylon or polyamide (PA) is a well-known material in the field of engineering and one of the most demanded nowadays for 3D printing. It is a highly versatile thermoplastic polymer that is very tough while maintaining high impact, chemical and thermal resistance. Polyamide 12 (PA12) contains twelve carbon atoms in its monomeric structure, unlike PA6 or PA11. Although their properties are similar, PA12 has the lowest moisture uptake giving better long-term results (less cracking). 3D printing with PA12 is used to replace functional injection molded parts, with very good chemical and thermal resistance.