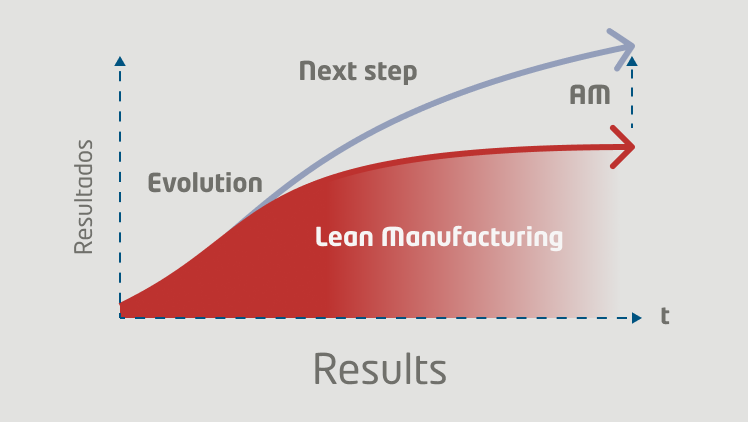

Process boosting

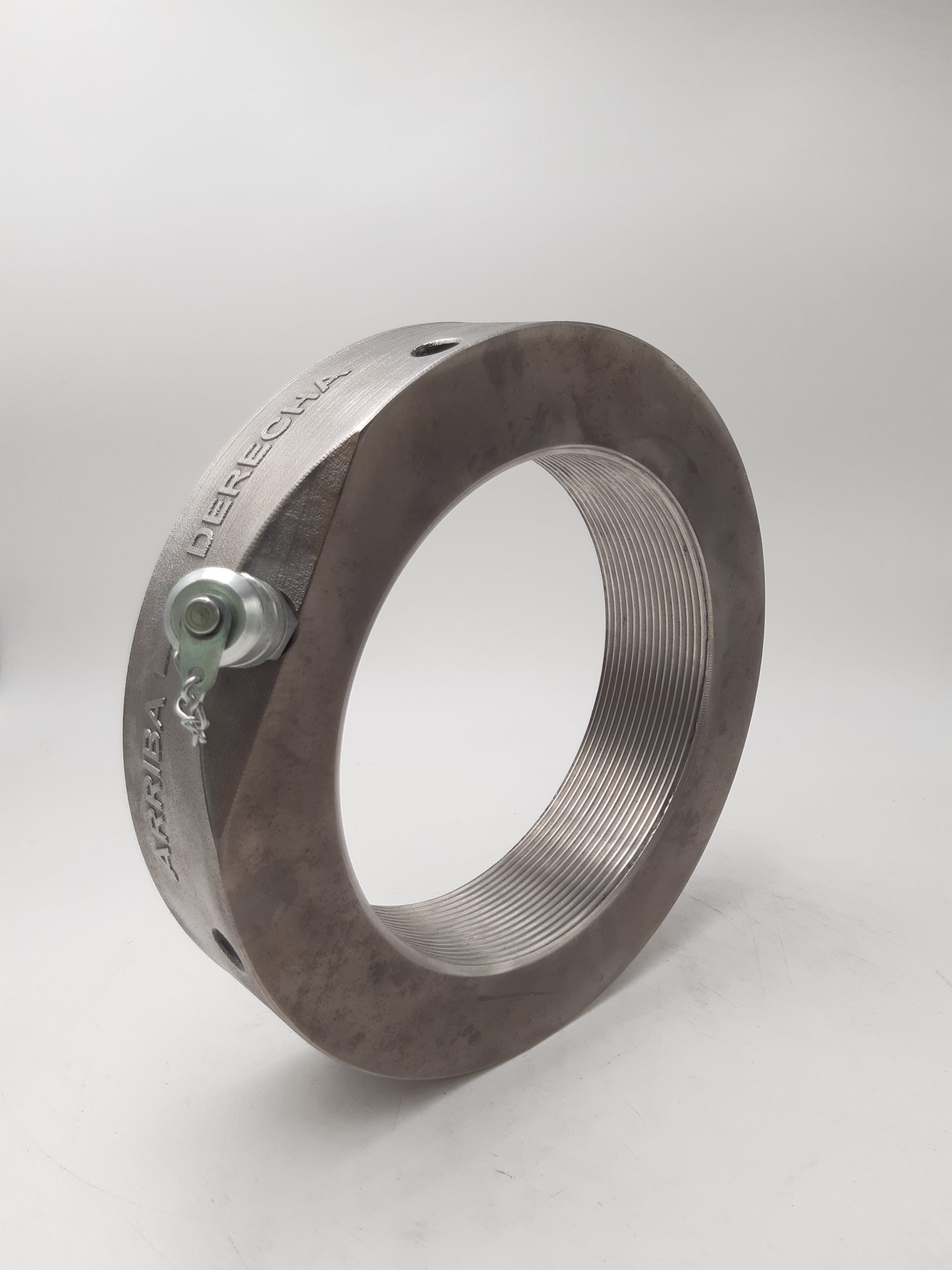

This service uses 3D printing or additive manufacturing as another lean manufacturing tool with the aim of reducing halts in production, increasing process efficiency, and improving process safety. Thanks to the wide range of industrial processes we are exposed to, we have extensive and varied experiences when it comes to the resolution of production problems related to poorly designed process tooling, made with unsuitable or too heavy materials.