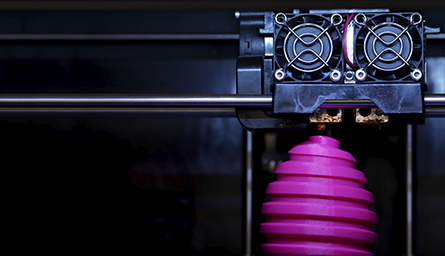

3D printing with Polypropylene

Polypropylene (PP) is a semi-crystalline thermoplastic widely used in the industry due to its low cost, for example, a third of the plastics used in a car are polypropylene. However, the prototyping of parts made in PP is not as common as its high-volume manufacturing. 3D printing with polypropylene is ideal for quick prototypes and the validation of designs that will be subsequently injected.