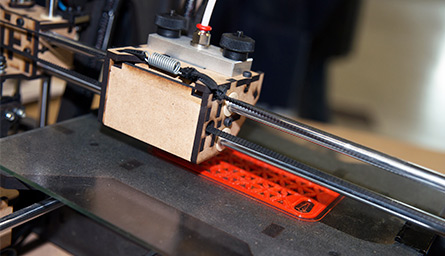

FDM 3D printing technology

Fused Deposition Modelling (FDM) printing technology is the most popular of the 3D printing technologies on the market. 3D plastic FDM printers cast a filament of a thermoplastic polymer to deposit it over a solid layer that was previously deposited, the heat of the casted material then recasts the solidified layer so that both join and form a uniquely printed item. The joining between the layers is also added to by the pressure exerted by the protruding cast of the 3D printer over the solid layer.