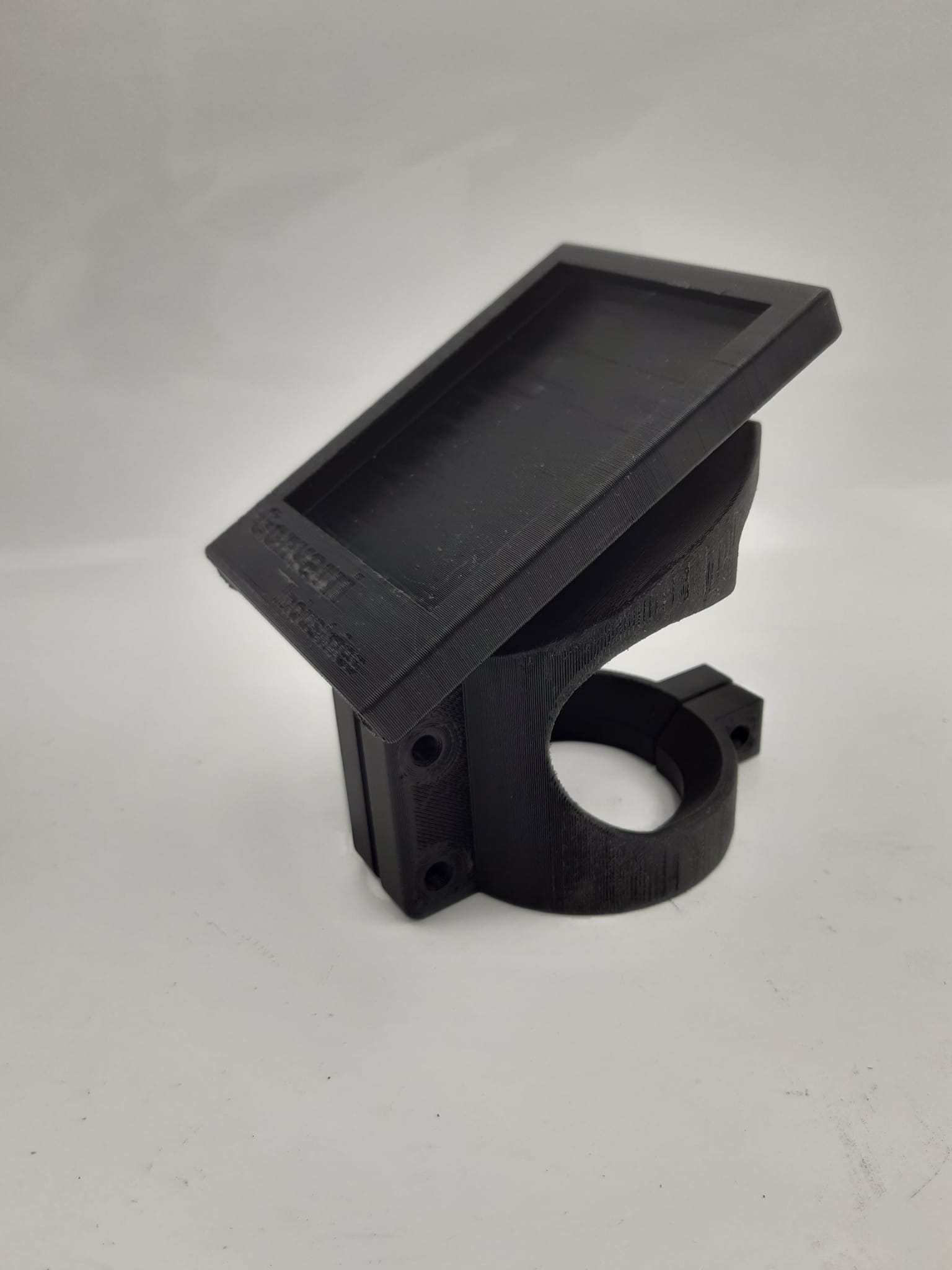

Prototyping and short runs

One of the most popular uses of 3D printing is the manufacturing of single units or short-run plastic or metal items. Among the various advantages of 3D printing is that no tooling or mounts are required for the manufacturing of 3D parts in plastic or metal. This means designers are able to quickly iterate and validate their designs, reducing the time it takes for products to reach the market. 3D printing technology and the postprocesses used at Addimen result in the production of fully functional parts in record time.