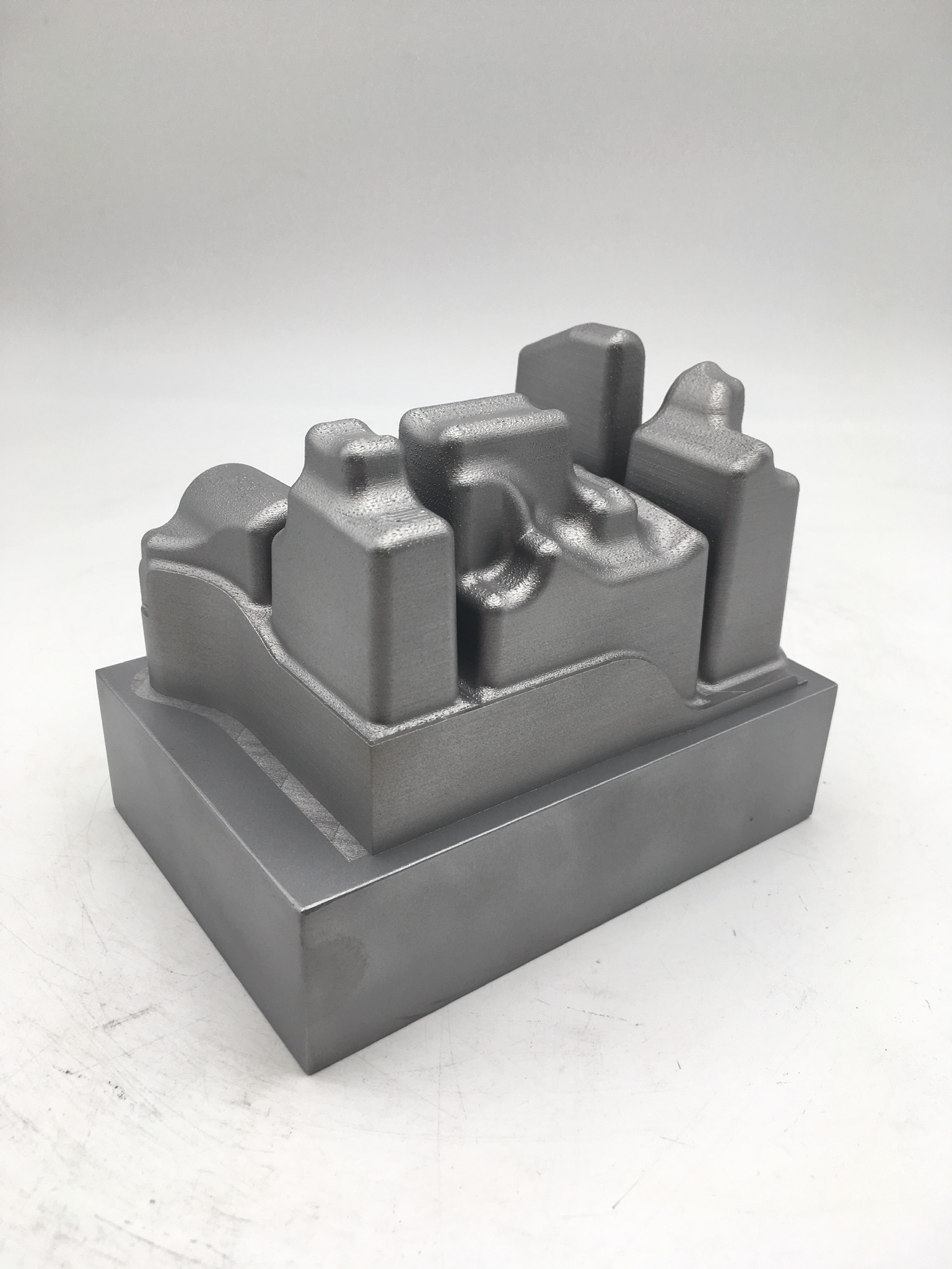

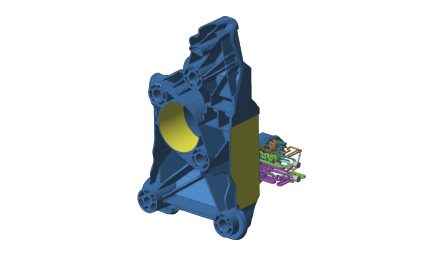

Mould Inserts

One of the great benefits of 3D printing with metal is what can be done to the inside of the parts. Using 3D metal printing in mould inserts with plastic or aluminium injections is one of our specialities. Our conformal channel or conformal cooling designs optimise the cooling of the mould resulting in shorter cycle times, more temperature homogeneity , and a reduced number of quality defects.