3D printing technology

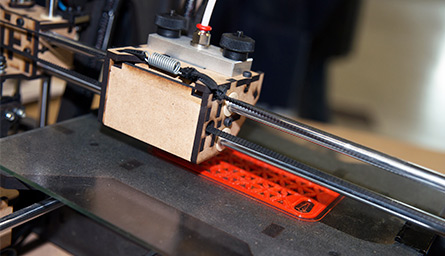

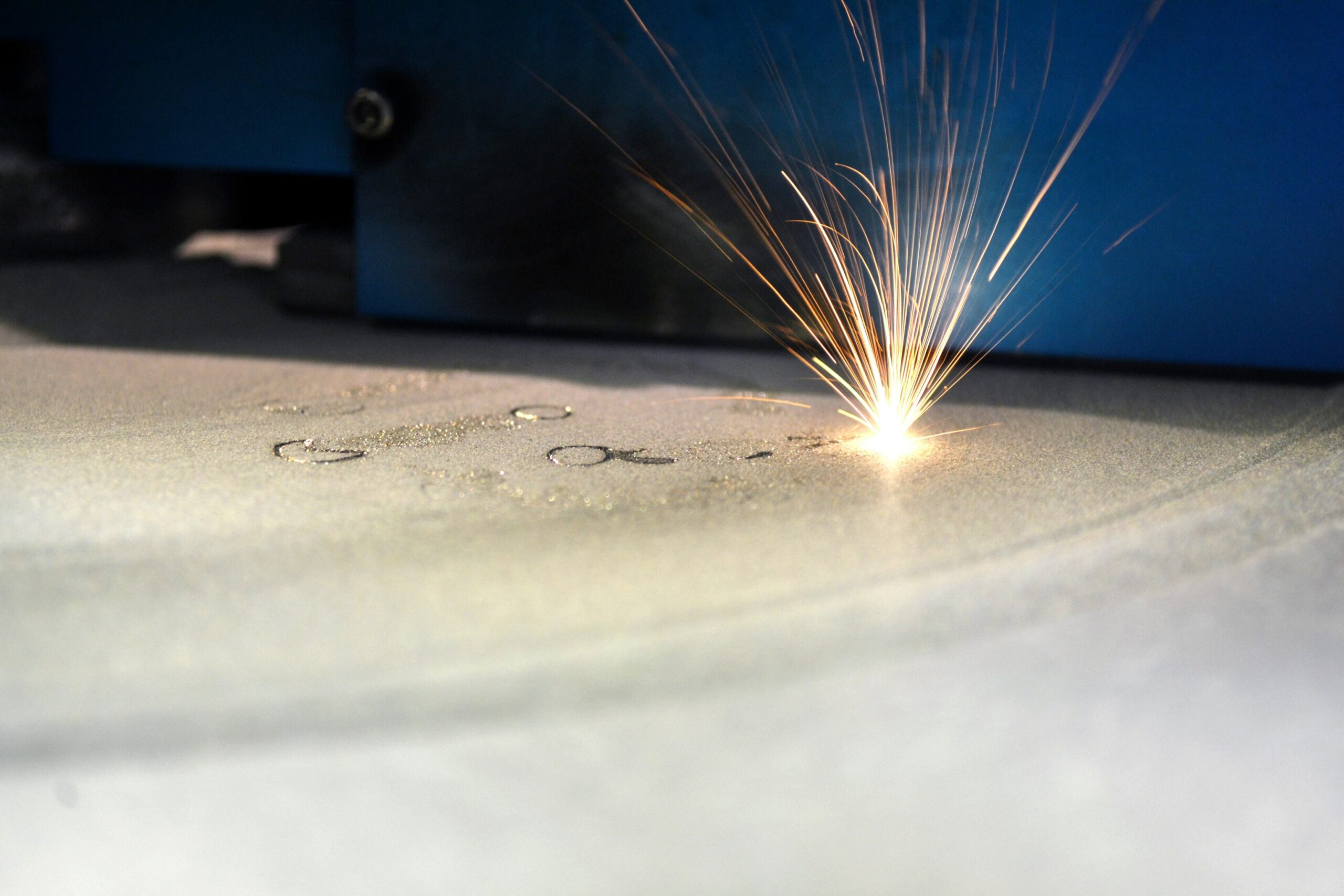

There are a range of 3D printing technologies, both for printing with metal and plastic, but not all of them offer the same quality, robustness, or variety of materials. In the case of 3D printing with metal materials, there is a choice of direct deposition technology such as Laser Cladding, or powder bed technology for metal printing with binder, electron beam melting (EBM), or selective laser melting (SLM). For 3D printing with plastic there is a larger choice available, with the most common being stereolithography (SLA), fused deposition modelling (FDM), binder jetting, or selective laser sintering (SLS).